2025-04-02 09:55:22

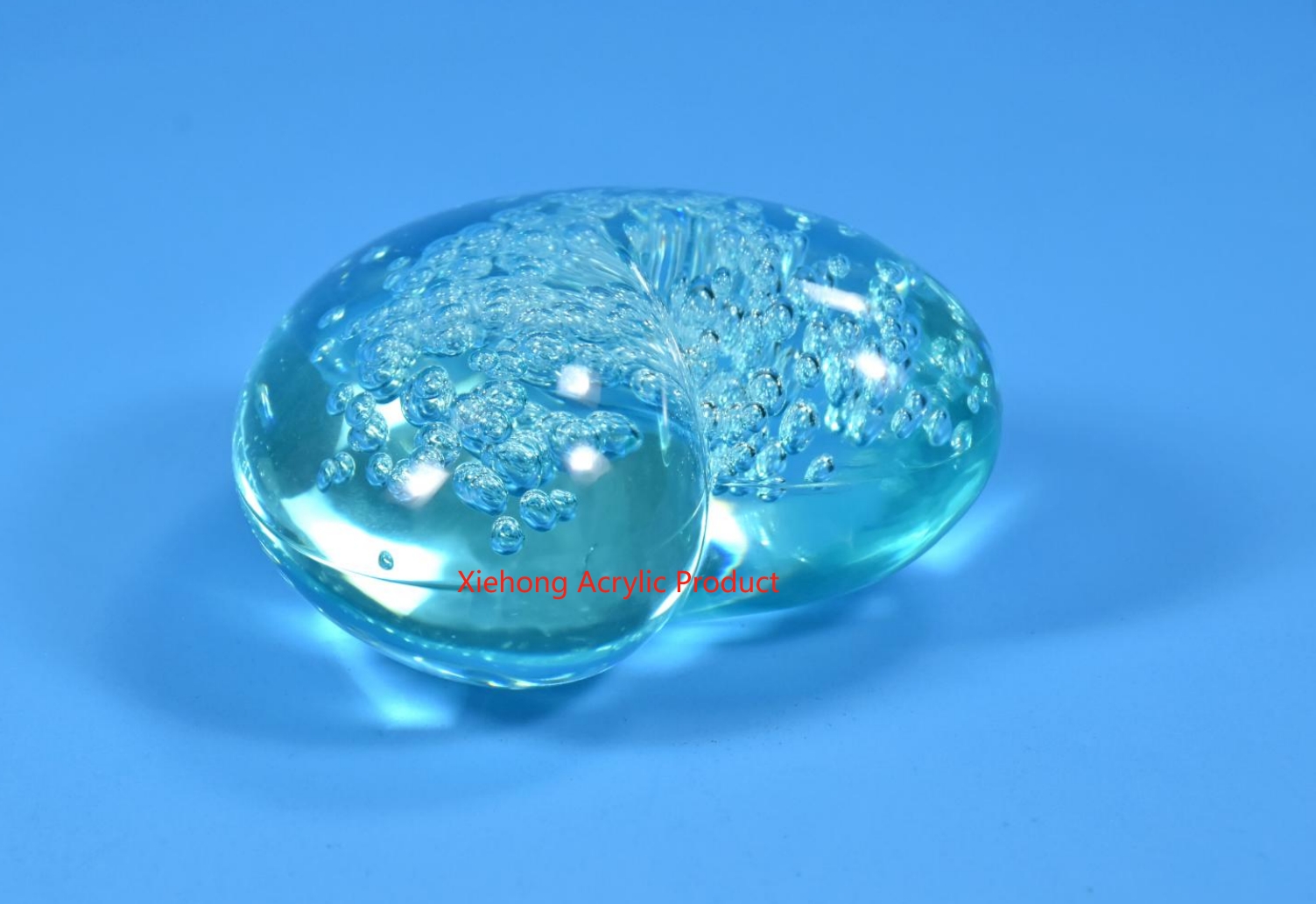

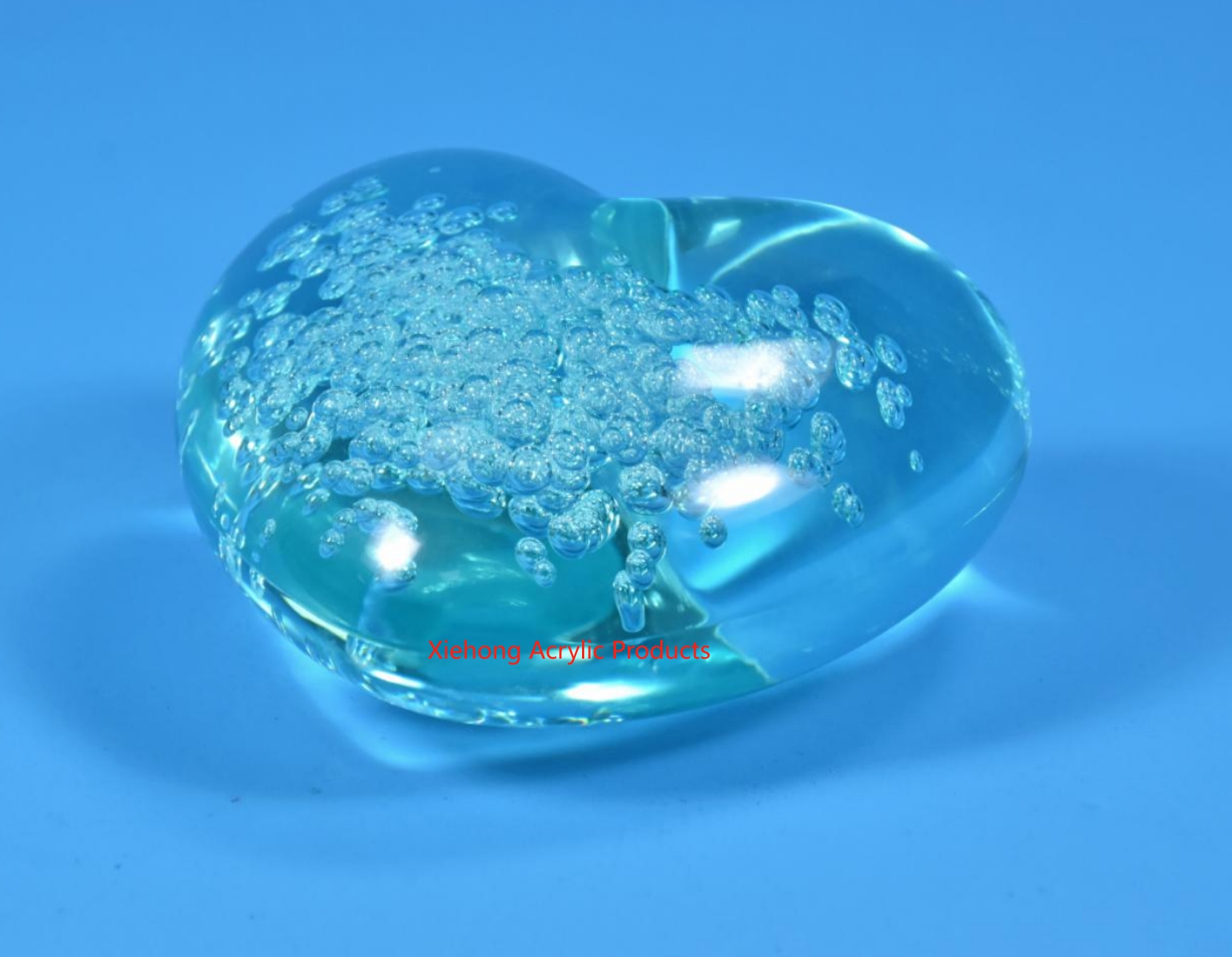

Air bubbles refer to small bubbles present within plastic parts. What are the causes of air bubbles in injection molded parts?

Firstly, in terms of the injection molding process:

Excessive injection speed:

If the injection speed is too high, it can trap air within the molten plastic.

Overly high melt temperature:

High melt temperatures can cause the plastic to degrade, releasing gases that form bubbles.

Excessive screw decompression:

If the screw retracts too much, it can draw air into the melt.

In terms of mold design:

Improper gate quantity or location:

Incorrect gate placement can hinder proper venting, trapping air.

Significant structural variations:

Parts with large steps or drastic curved surfaces may trap air during filling.

Excessive holes or grids:Complex designs with numerous holes or grids can make it difficult to vent air effectively.

Copyright Xiehong Plastic Mold and Manufacturing Tech Co., Ltd. All rights reserved.